The full name of TFT is Thin Film Transistor (thin film field effect transistor), which means that each liquid crystal pixel on the liquid crystal display is driven by a thin film transistor integrated behind it, so that a high-speed, high-brightness, high-contrast display screen can be achieved. Information, TFT is an active matrix liquid crystal display, and TFT-LCD (Thin Film Transistor Liquid Crystal Display) is a type of most liquid crystal displays.

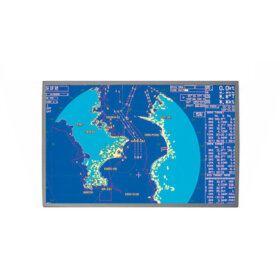

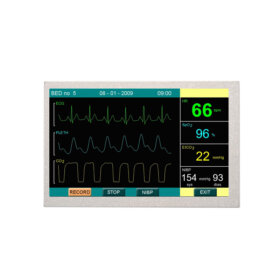

Youritech offers a range of TFT display options that meet industrial standards, including modules such as IPS TFT, High Brightness TFT LCD (sunlight readable), Bar Type TFT, Wide Temperature TFT LCD, and others. These displays can be used in landscape or portrait orientations and come in both Mono and full-color options with various resolutions. Touch screen capabilities are available in resistive and projected capacitive (PCAP touch screen) technologies. These display modules support multiple interfaces such as MCU, RGB, TTL, LVDS, and MIPI DSI, making them versatile for applications in industrial control, medical equipment, POS systems, automation, GPS navigation, and more.

High display quality

TFT with Full Range of Viewing Angles

Wide Application Range of TFT-LCD Display

Wide Use of Application Temperature

Good Color Performance

Low Power Consumption

Televisions and home theater systems

Gaming consoles

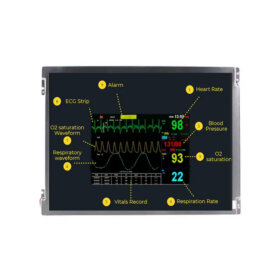

Medical monitors

Automotive infotainment systems

Industrial human-machine interfaces

Public information displays

Consumer electronics products

Automobile industry

Medical equipment

Aerospace

Industrial applications.

TM185VDSG06 Displays

TM185VDSG06 Original 18.5 Inch 1920x1080 eDP TFT LCD Display

TM185VDSG07 Displays

TM185VDSG07 Original 18.5 Inch 1024x768 LVDS TFT LCD Display

TM150TDSG81 TFT Display

TM150TDSG81 Original 15 Inch 1024x768 eDP TFT LCD Display

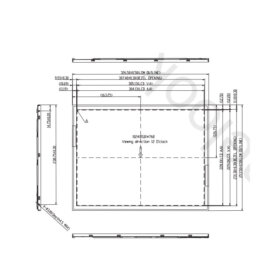

P1210XGF1MA01 LCD Display

P1210XGF1MA01 Original 12.1 Inch 1024x768 High Brightness Wide Temperature TFT LCD Display

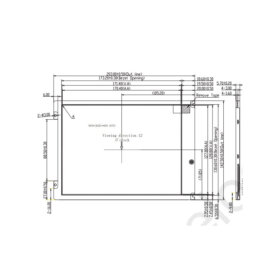

P1210SVF1MB00 Displays

P1210SVF1MB00 Original 12.1 Inch 800x600 LVDS TFT LCD Display

TM104TDGP13-00 Displays

P1040XGF1MA00 Original 10.4 Inch 1024x768 Ultra High Brightness Wide Temperature TFT LCD Display

P0840XGF1MB00 Displays

P0840XGF1MB00 Original 8.4 Inch 1024x768 High Brightness Wide Temperature TFT LCD Display

P0840SVN1MB00 Displays

P0840SVN1MB00 Original 8.4 Inch TFT LCD Display 800x600 LVDS LCD Module

TM104SDH02 Displays

TM104SDH02 Tianma 10.4 Inch 800x600 Wide Temperature LVDS LCD Display

TM104SDH01-00 Displays

TM104SDH01-00 Tianma 10.4 Inch TFT LCD Display 800x600 LVDS LCD Module

TM101JDHG32-00 LCD Display

TM101JDHG32-00 Tianma 10.1 Inch TFT LCD Display 1280x800 Ultra High Brightness LCD Display

TM101JDHP03-00 TFT Display

TM101JDHP03-00 Tianma 10.1 Inch TFT LCD Display 1280x800 LVDS LCD Module

TM101JDHG38-00 Displays

TM101JDHG38-00 Tianma 10.1 Inch TFT LCD Display 1280x800 LVDS LCD Module

TM101JDHP01-00 Displays

TM101JDHP01-00 Tianma 10.1 Inch TFT LCD Display 1280x800 LVDS LCD Module

P1010WSN1ME00 Displays

P1010WSN1ME00 Tianma 10.1 Inch TFT LCD Display 1024×600 LVDS LCD Module

TM084SDHG01-01 Displays

TM084SDHG01-01 Tianma 8.4 Inch TFT LCD Display 800x600 LVDS LCD Module

TM080TDGP02-00 TFT Display

TM080TDGP02-00 Tianma 8 Inch TFT LCD Display 1024×768 LVDS LCD Module

P0700WVF1MA00 TFT Display

P0700WVF1MA00 Tianma 7 Inch TFT LCD Display 800×480 Sunlight Readable LVDS LCD Module

TM070RDSG12-00 Displays

TM070RDSG12-00 Tianma 7 Inch TFT LCD Display 800×480 LVDS LCD Module

P0700WVN1MB01 Displays

P0700WVN1MB01 Tianma 7 Inch TFT LCD Display 800x480 TTL LCD Module

P0700WVN1ME01 Displays

P0700WVN1ME01 Tianma 7 Inch TFT LCD Display 800x480 Parallel RGB LCD Module

P0650VGF1MA10 Displays

P0650VGF1MA10 Tianma 6.5 Inch TFT LCD Display 640×480 Sunlight Readable LVDS LCD Module

P0650VGF1MA00 IPS Display

P0650VGF1MA00 Tianma Original 6.5 Inch TFT LCD Display 640x480 Sunlight Readable LVDS LCD Module

LQ190E1LX76 Displays

LQ190E1LX76 Sharp 19 Inch TFT LCD Display 1280×1024 LVDS LCD Screen For Industrial

LS121K1LX02 TFT Display

LS121K1LX02 Sharp 12.1 Inch TFT LCD Display 1280×800 LVDS LCD Module

LS022B7DH03 IPS Display

LS022B7DH03 Sharp 2.2 Inch TFT LCD Display 240x320 Transflective 3-wire SPI LCD Module

COM104H9M25SSS Displays

COM104H9M25SSS Original 10.4 Inch TFT LCD Display 800×600 LVDS Sunlight Readable LCD Panel

ET185FH01-OT Displays

Factory OEM ODM 18.5 Inch TFT LCD Display USB LCD Panel With Touch Display

ET070WU12-O Displays

Factory Custom 7 Inch TFT LCD Display 1200×1920 MIPI High Brightness LCD Panel

ET041HD03-OT TFT Display

Factory OEM ODM 4.13 Inch TFT LCD Display 1200×720 MIPI LCD Panel

ET070WV02-CT Displays

Factory OEM ODM 7 Inch TFT LCD Display 800×480 LVDS High Brightness LCD Panel

ET070WX05-OT Displays

OEM ODM 7 Inch TFT LCD Display 800×1280 MIPI LCD Panel For Industrial

ET070WU07-OT IPS Display

Factory OEM ODM 7 Inch TFT LCD Display 1200×1920 MIPI LCD Panel

ET070WU11-OT LCD Display

Factory Custom 7 Inch TFT LCD Display 1200×1920 MIPI LCD Panel ET156D1JW31 3840x2160 15.6 inch laptop display 40 pins 4k lcd module IPS display

ET156D1JW31 3840x2160 15.6 inch laptop display 40 pins 4k lcd module IPS display

3.5inch ips lcd full viewing angle 640x480 lcd MIPI RGB interface landscape 3.5" tft panel

3.5inch ips lcd full viewing angle 640x480 lcd MIPI RGB interface landscape 3.5" tft panel

10.1inch custom lcde 1200x1920 display mipi interface 10.1" ips lcd screen full viewing angl

10.1inch custom lcde 1200x1920 display mipi interface 10.1" ips lcd screen full viewing angl

high quality 10.1 inch 1920x1200 IPS TFT LCD display WITH LVDS (2ch) 40pin interface for medical

high quality 10.1 inch 1920x1200 IPS TFT LCD display WITH LVDS (2ch) 40pin interface for medical

7 inch ips lvds tft 1280x800 40pins LVDS WLED TFT LCD Display with wide viewing angel

7 inch ips lvds tft 1280x800 40pins LVDS WLED TFT LCD Display with wide viewing angel

ET156Z1JW01 15.6 inch LCD panel 3200x1800 QHD IPS LCD Display for Laptop

ET156Z1JW01 15.6 inch LCD panel 3200x1800 QHD IPS LCD Display for Laptop

ET133DSE-GP1 13.3 4K LCD 3840x2160 IPS EDP 40 PIN 72%NTSC Lcd Screen Module

ET133DSE-GP1 13.3 4K LCD 3840x2160 IPS EDP 40 PIN 72%NTSC Lcd Screen Module

ET024QV02-V 2.4inch LCD 240*320 resolution ST7789V IC TN MODE cheapest

ET024QV02-V 2.4inch LCD 240*320 resolution ST7789V IC TN MODE cheapest

COM20T2P31ILC Ortustech 2 Inch TFT LCD Display 240×320 CPU/RGB/SPI LCD Panel

COM20T2P31ILC Ortustech 2 Inch TFT LCD Display 240×320 CPU/RGB/SPI LCD Panel