Writer: adminRelease Time: 2025-08-15 07:48Browse: 786

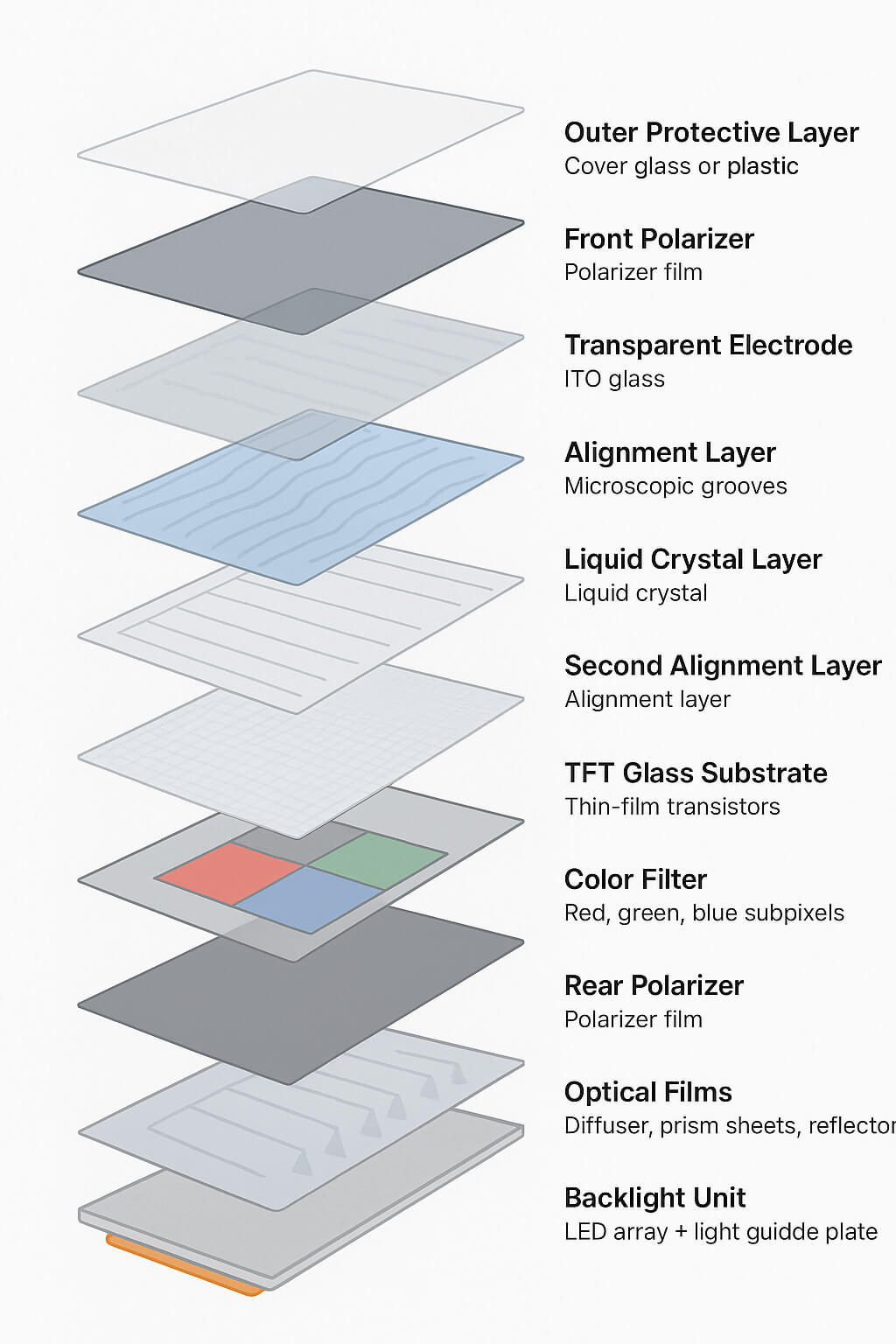

An LCD (Liquid Crystal Display) panel is made up of multiple precisely layered structures, each playing a specific role in producing the final image. From top (viewer side) to bottom (backlight side), the main structures are:

Protects the panel from scratches, impact, and environmental damage.

Often includes anti-glare, anti-reflective, or anti-fingerprint coatings.

A special optical filter that allows light waves of only one polarization to pass.

Essential for controlling light through liquid crystals.

Made of indium tin oxide (ITO) coating on glass.

Forms one set of electrodes to apply voltage to the liquid crystal layer.

Microscopic grooves on the electrode surface that align the liquid crystal molecules in a specific direction before voltage is applied.

The core active layer.

Liquid crystals twist or untwist when voltage is applied, controlling light passage.

Works with the top electrodes to form pixel control.

Usually paired with a thin-film transistor (TFT) array on the glass for pixel-by-pixel switching.

Contains the thin-film transistors and pixel electrodes that control each subpixel’s voltage.

Works as the “control circuit” embedded directly into the display.

Red, green, and blue subpixel filters create full-color images when combined.

Includes a black matrix to prevent light leakage between subpixels.

Oriented perpendicular to the front polarizer.

Works with the liquid crystal twisting effect to block or pass light.

Diffuser spreads light evenly.

Prism sheets focus light toward the viewer for higher brightness.

Reflector returns stray light into the backlight.

Usually an LED array + light guide plate (LGP).

Provides a uniform light source since liquid crystals don’t emit light themselves.

LCD Displays & OLED Display product links for reference:

https://www.youritech.com/products/ips-displays/