Writer: adminRelease Time: 2025-07-04 05:44Browse: 586

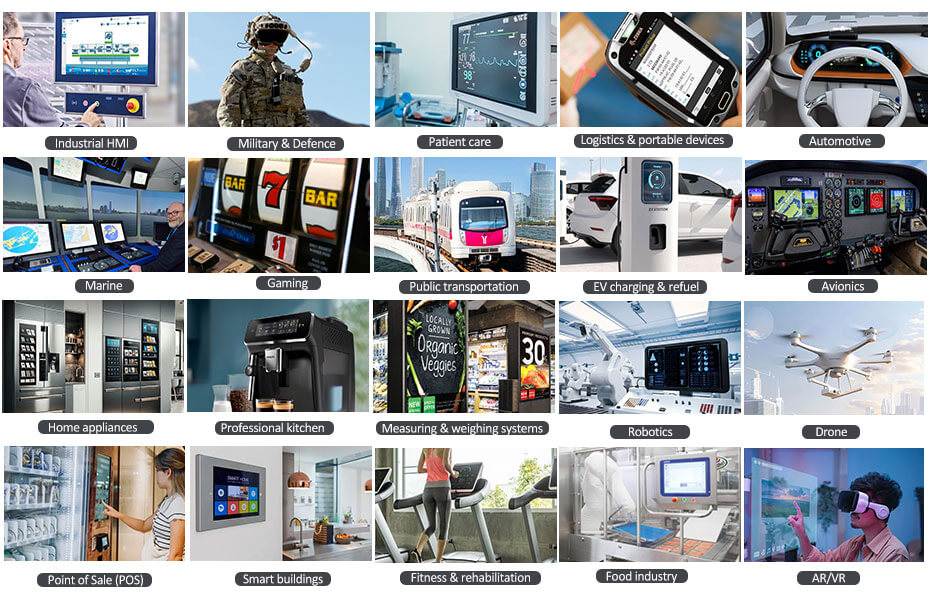

Creating a waterproof touch screen for outdoor and industrial applications requires careful integration of several components and protective design features.

Projected Capacitive (PCAP): Best for waterproofing and multi-touch functionality. Works through glass or plastic cover lenses.

Resistive Touch: Less ideal outdoors; pressure-based, not suitable for gloved use in rain or when wet.

Infrared/Optical Touch: Less reliable in harsh or dirty environments.

Recommended: PCAP touch with water rejection algorithms for outdoor/industrial use.

Optical Bonding fills the air gap between the touch sensor and display with a transparent adhesive:

Improves readability in sunlight.

Prevents moisture/condensation.

Strengthens durability

Use chemically strengthened glass (e.g., Gorilla Glass) or a tough PMMA layer.

Seal the edges with waterproof gaskets or silicone.

Thickness: 0.7mm–2mm depending on impact requirements.

Target IP65, IP67, or IP68 rating depending on exposure:

IP65: Protected against low-pressure water jets.

IP67: Withstands immersion up to 1m for 30 mins.

IP68: Long immersion and pressure resistance.

Use rubber gaskets, waterproof glue, and sealed ports.

Apply nano-coatings on the surface to repel water, oil, and dust.

Enhances visibility and usability during rain or moisture contact.

Firmware should handle:

Moisture rejection algorithms.

Glove and water detection.

Temperature compensation for extreme hot/cold weather.

Perform:

Waterproof testing (spray, immersion).

Temperature cycling (-20°C to +70°C or more).

UV exposure testing.

Vibration/shock testing for industrial grade.

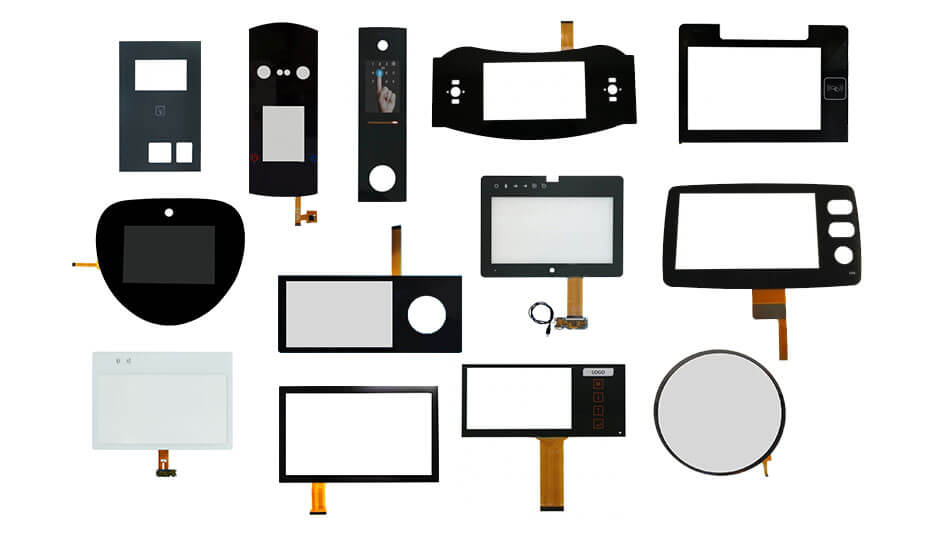

PCAP Touch Displays product links for reference:

https://www.youritech.com/products/capacitive-touch-displays/

Shenzhen Youritech Technology Co.,Ltd. focuses on the research and development ,design ,customization and production of LCD,OLED,touch screen and other products.

website:https:www.youritech.com

Contact information:[email protected]