Writer: adminRelease Time: 2025-07-11 05:54Browse: 385

Here's a comprehensive analysis of the waterproof requirements for touchscreens and displays, especially relevant for outdoor, industrial, medical, marine, or rugged applications:

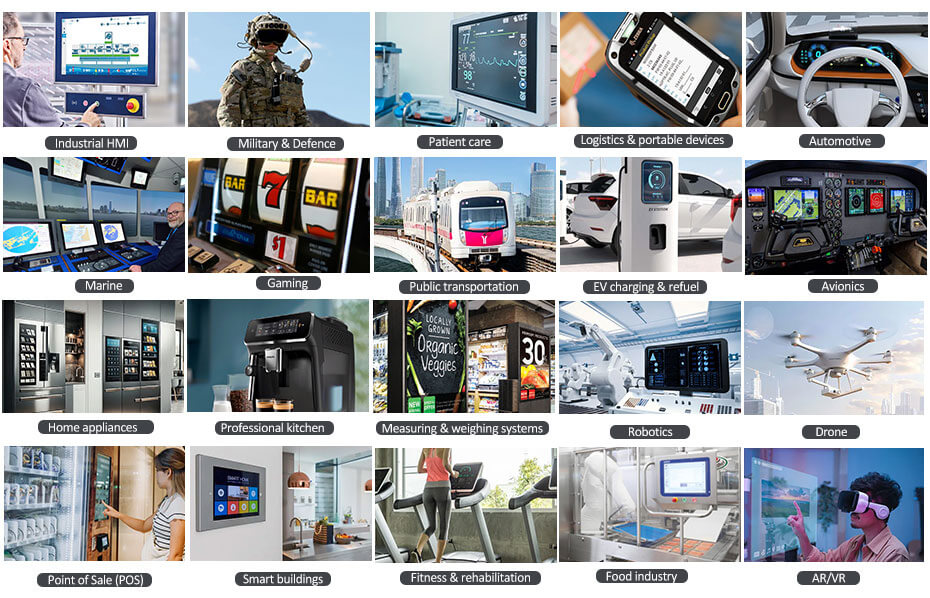

Waterproofing is critical for touchscreens and displays used in:

Outdoor environments (kiosks, smart parking meters)

Industrial applications (factory automation, process control)

Medical devices (to allow disinfection and cleaning)

Marine and vehicle systems

Wearable or handheld devices exposed to moisture, rain, sweat, or cleaning agents

Without proper waterproofing, water ingress can lead to:

Short circuits

Display damage (fogging, corrosion)

Touch malfunctions or ghost touches

Reduced lifespan and reliability

The most common classification system:

IP65: Dust-tight, water jets from any direction

IP67: Dust-tight, immersion up to 1 meter for 30 minutes

IP68: Dust-tight, long-term submersion under pressure

IP69K: Protection against high-pressure, high-temperature water jets (ideal for food and pharmaceutical industries)

Similar to IP, but includes corrosion and gasket integrity ratings.

PCAP (Projected Capacitive): Preferred for waterproof use, works through protective glass or plastic, supports multi-touch, and is sealable.

Resistive: Less suited due to membrane vulnerability; water pressure can trigger false touches.

Infrared/SAW: Generally not waterproof and sensitive to water drops.

Bonding the touch sensor to the LCD using an optically clear adhesive (OCA or OCR) eliminates the air gap, reducing moisture ingress and improving visibility in humid conditions.

Gasket sealing (silicone, foam)

O-ring designs for enclosure joints

Overmolded bezels for outdoor kiosks

Fully laminated cover lenses (glass or polycarbonate)

Cover Lens: Waterproof, chemically strengthened glass or waterproof plastics like polycarbonate

Coatings:

Hydrophobic/Oleophobic to repel water and oils

Anti-reflective for outdoor visibility

Waterproof adhesives for laminating display stacks

Water immersion testing

Rain simulation

High-pressure hose spray testing (IP69K)

Salt fog and corrosion tests (marine/industrial)

Thermal cycling and condensation resistance

Maintaining touch sensitivity under wet conditions

Avoiding false touch inputs from water droplets

Condensation between layers if not properly sealed

Balancing waterproofing with thermal dissipation needs

Select PCAP touch panels with glove and water support algorithms

Ensure full bonding and IP67/IP68 sealing for exposed areas

Use venting membranes to equalize pressure while keeping water out

Integrate sunlight-readable LCDs with anti-condensation features for outdoor

Designing a waterproof touchscreen or display requires a multi-layered approach—choosing the right touch technology, sealing methods, materials, and conforming to appropriate IP/NEMA standards. Optical bonding and PCAP technology have made high-performance waterproof displays both feasible and reliable, even in the most demanding environments.